Refurbishing a Sievers table loom

Refurbishing old looms is great fun. I learn something new each time I do it. I have a not-so-secret dream of collecting little looms, fixing them up, and starting a weaving school.

Meet Marigold. She’s a Sievers table loom I bought off Craigslist. The seller said the loom was in “salvage” condition – but apart from surface mildew and rust, she looked just fine to me. The wood wasn’t warped or split.

The Sievers School still exists (it’s in Wisconsin), but no longer sells looms or plans. There were some interesting tidbits on Sievers’ blog about their history.

The first step was to disassemble Marigold and clean the wood. I read that vinegar was great for killing mold spores, so I got the worst of it off with a warm vinegar/water mixture, then cleaned her all over with Murphy’s oil soap. So much better already!

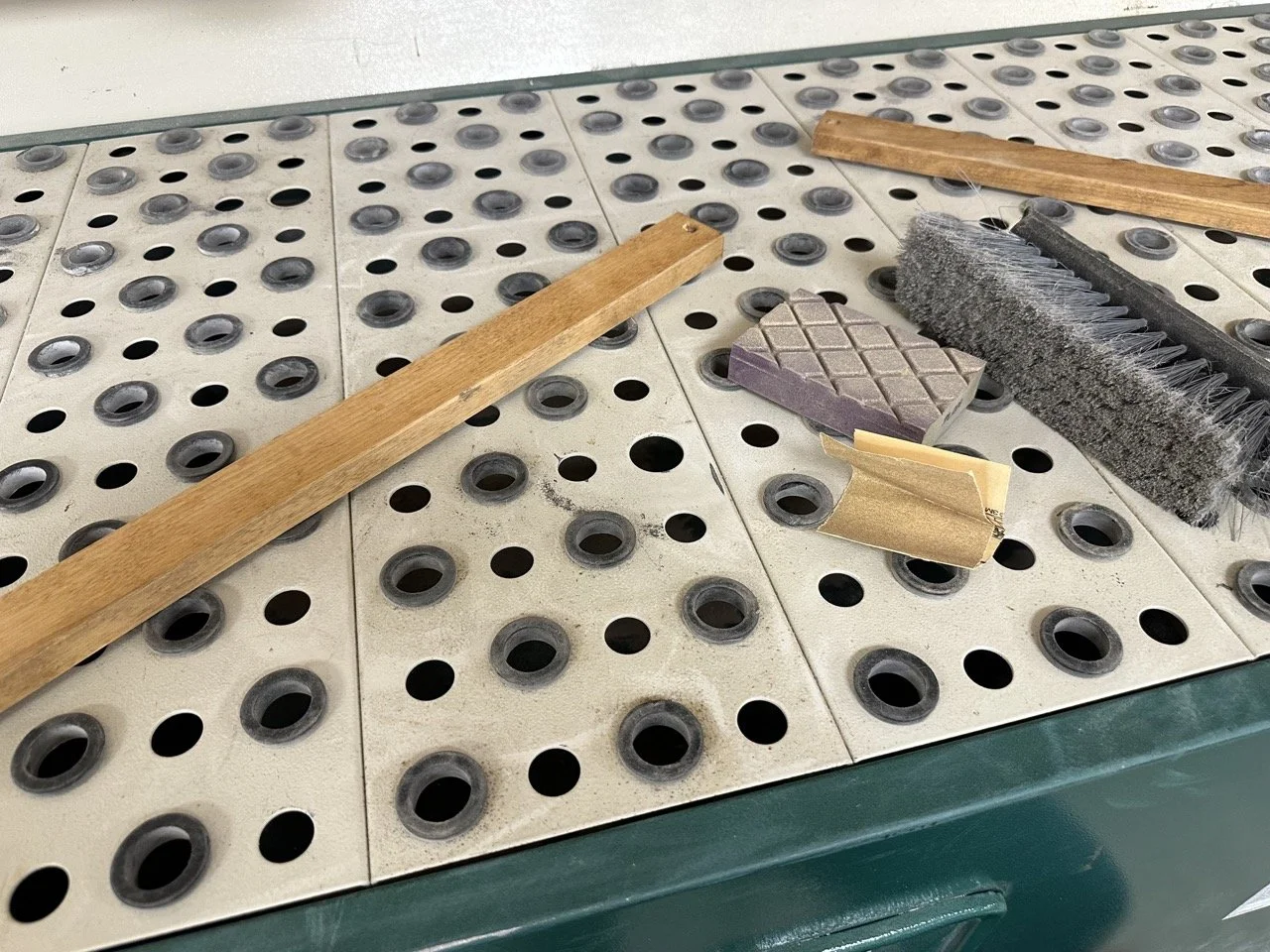

Once dry, I brought her in to the makerspace for a nice sanding (150 grit, then 220). They have an AMAZING downdraft table in the woodshop – I never want to sand anywhere else.

At home, I took my bin of sanded pieces and wiped them down with tacky microfiber cloth to remove any remaining wood dust. Then, I coated the wood with Feed & Wax. It’s so soft and smooth now.

Next up was the hardware. I refreshed any usable pieces with vinegar, steel wool, and WD-40, and replaced any screws or bolts that were rusty or corroded. My partner also found a sturdy spring for the shaft holders.

I completely replaced the heddles. The ones that came with the loom were very thin and had spots of corrosion. Probably not worth saving. I still had Edna’s original flat steel heddles and luckily those fit!

And the finishing touches:

I cleaned the ropes that raise and lower the shafts. They were in good condition so I just soaked them in warm vinegar and water, then washed with soap.

I also attached a front/back bar for securing the warp. I did this with cotton seine twine and wooden dowels for now. The dowels work but are a bit flexible. I have a steel rod to replace them – it just needs to be trimmed down to size.

After refinishing any loom, the next step is to put a warp on and see how she weaves. My test project was the “My Art Hath” weaving / unweaving / reweaving project I shared in my last post.

Marigold weaves great! I set her up for 1-3 and 2-4 plain weave. Midway through, I ended up switching the ropes on the shafts 2 and 3 to make changing the shed easier. This way, I could press levers 1/2 or 3/4 together, instead of 1/3 and 2/4, which requires a little more precision.

The last modification I made was to put a piece of craft foam on the top of the loom where the shaft “stop” is. This helps dampen the sound when changing sheds.

She’s such a lovely little loom, and reasonably portable, too! I plan on bringing her to craft night at SJMQT so I can sley and thread my next project while socializing.